|

the final washed PET bottle flake total impurity within 50ppm

food grade PET bottle washed flake

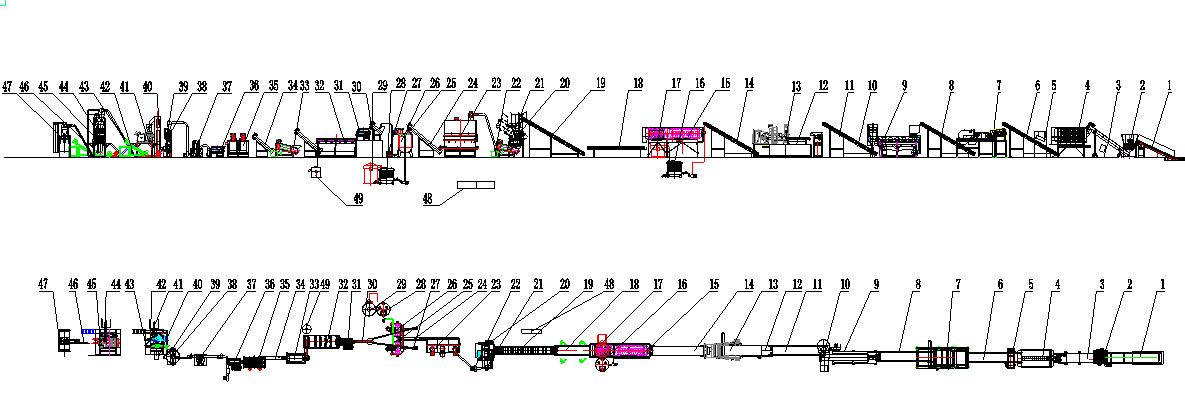

PET bottle washing line /PET bottle recycling plant/PET recycling process

PURUI Recycling Machine (Label Separating, Crushing, Washing, Drying and Granulating)

PET Bottle Recycle Washing Machines are special designed for PET bottles with sand, stone, powder, oil and other sticky waste.

Capacity range: 500kg/h to 6500kg/h

Food Grade PURUI PET bottle recycle washing line features:

1. bale breaker benefit labor saving

2. delabel system and label removing system can remove bottle label with 99.9%

3. Plastic bottle label separating, cutting, washing, recycling machine with high output and excellent clean ability

4.Simple structure, easy operation, large capacity, energy-saving, safety

5.Automatic controlling, compacted structure, excellent production ability, perfect clean ability

Machine Working Process:

Machine Running Video Reference

https://youtu.be/0CxGpl6Uidk

1. Iron board, four shaft bale breaker | |

Function: to open the bottle bale frequency conversion Basic material of chain: Iron |

|

Double spiral feeder | |

To convey material through spiral into next part be made from carbon steel |

|

4. Trommel | |

Function: to remove stone, dust, loosen caps and small metal Basis material: Galvanized carbon steel Frame: Carbon steel Diameter of barrel : 1800mm Length : 7000mm Motor power: 11kW The hole diameter:50mm Bottom discharge belt material: PVC

|

|

Function: bottles conveying Basic material of belt: PVC Motor power: 3kW frequency conversion Storage bottle |

|

6. Magnetic separator | |

Function: to remove ferrous as iron, chromium and manganese Power:3kW Magnetic strength: 900 G S

|

|

7,8 Eddy current separator, crack and discharge belt conveyor | |

PLC independent control To sorting out iron, aluminum, stainless steel, non-magnetic separation of metals

|

|

10. Bottle Label Separator | |

Function: to remove above label:98% Labels for both common and compressed bottle: 95% No flakes waste and no water consumption

|

|

12,13 Optical sorting, vibrating feeder | |

PVC or color sortor (near infrared light optical sortor) Customer can buy on their own To separate PVC bottle and color bottle

|

|

| |

15,16,17 pre-washer, round vibration and heat preservation water tank | |

Function: to wash bottle and remove small size impurity, decrease the working pressure for down stream Basis material: Galvanized carbon steel Frame: Carbon steel 304Diameter Touching material: stainless steel Heat preservation water tank volume: 4 m3 Water pump motor: 4kW Touching material is stainless steel

|

|

18. Sorting belt conveyor | |

Function: bottle conveying and remove the labels sort color and material rejected by manual Width of belt: 1200mm Basic material of belt: PVC

|

|

19. PSJ1200 Crusher | |

Motor: 132kW Crusher brand: ZERMA Rotating diameter: 800mm Crushing room width:1200mm Mesh size:16mm Rotary cutters: 14pcs Fixed cutters: 6 pcs, 3 groups Cutter material: SKD-11 Rotating speed:600rpm Compressed system: 11kW |

|

21,22 friction washer and water filtering wind system | |

Friction washer main motor:37kW Rotating diameter: 650 *1400 Touching material: 304 stainless steel Main shaft: 201 and 301, others are carbon steel Touching material: 304 stainless steel, others are carbon steel

|

|

23. Storage feeder | |

30 m3 Touching material: 304 stainless steel Other are carbon steel Frequency inverter control Frequency inverter control the feeder motor, relay control the mixing motor

|

|

24.25 Floating Washer | |

Spiral rotating diameter: 350mm Spindle stainless steel seamless tube wall thickness: 7mm Blade thickness: 4mm Box thickness: 3mm Touching material is 304 stainless steel

|

|

26. 27 high speed friction washer with feeding water pump | |

High speed friction washer Main shafts are made from 201 or 301 stainless steel, others are carbon steel To work in turn The bottom pneumatic valve switch get changed according to set time. The later feeding water pump get opened few second ahead. The front horizontal spiral get stopped few second advance with reverse-rotating.

To control the water supply switch of the insulation water tank. Feeding water pump: imported pump Touching material is 304 stainless steel, others are Carbon steel To work in turn

|

|

28,29 round vibration system and water preservation tank | |

Round vibration diameter: 2 meters Touching material: stainless steel Water preservation tank volume: 4 m3 Water pump motor: 4kW * 2 Touching material: stainless steel

|

|

30.31 filtering spiral and dewatering system | |

filtering spiral diameter: 350mm Spindle stainless steel seamless wall thickness: 7mm Blade thickness: 4mm Box thickness: 3mm Touching material: 304 stainless steel Main motor: 5.5kW Volume: 0.8m3 Centrifugal dewatering system motor: 45kW Rotating diameter: 350* 4000 Touching material: 304 stainless steel Main shafts are made from 201 or 301 stainless stee, Rotating speed; 1800rpm Mesh hole: 2.8mm Others are carbon steel

|

|

32. Floating Tank | |

Through floating force, flake and waste get separating and floating washing |

|

33. Friction washer | |

Through friction force with deeply remove impurity or sticky waste of flake

|

|

34 screw loader | |

To convey material into next part

|

|

35 floating and mixing unit | |

To do floating and mixing |

|

36. Centrifugal Dryer | |

To dry washed bottle flake with centrifugal force

|

|

37. pipe dryer | |

Through hot wind with drying flake |

|

38Flake Label Separator | |

Function: to remove the light impurity as dust and label

|

|

39. Vibration system | |

To shake the water on the surface of flake |

|

45,46 material sorting, crack resorting and wind transfering system | |

47. Packaging system(Vibrated packaging) | |

To do material package with two package mouth |

|

48. Electric Cabinet | |

Function: Electric control for the complete line Touch screen: SIEMENS(LG) PLC control module: SIEMENS(LG) Electric control component: (Schneider), e.g. Circuit-breaker, AC contact, press button, pilot lamp |

|