|

PET Non-woven cloth recycle pelletizing machine

ML130 PET non-woven pelletizing extruder

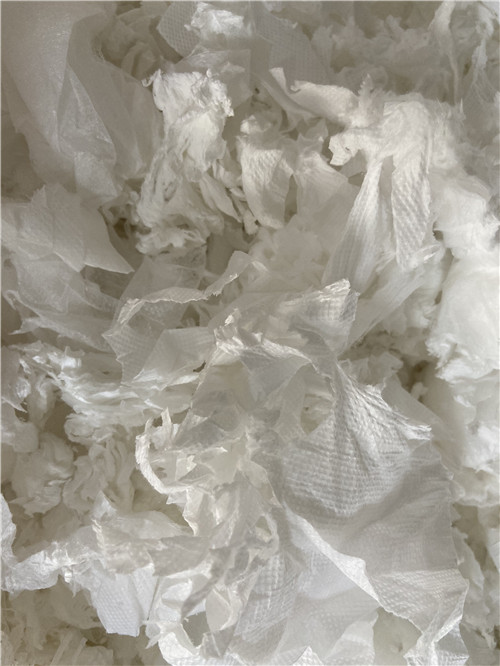

PURUI Plastic Recycling System/ Polyester Recycle Machine/ PET non-woven fabric recycling extruder/ PET recycling machine/Plastic Pelletizing Extruder

Process material:

PE/PP roll, Bags, film scraps, buddle film, film sheet, shrink film, garbage bags, stretch film, post-consumer bags, shopping bags, PP non-woven bag, cement bag, rotajet bags, washed flakes, fabric, polyester, PP mask trim edge

Main Features:

"three in one" recycling extruder without pre-cutting process

Frequency inverter monitor the compactor with balance feeding and cutting

2 grades roots pump for gas exhausting

Double column hydrualic screen changing benifit smoothly strip pulling processs

Pull strip pelletizing way

Touch screen control with easy operation

Main Technical Parameter

Normal

| Model | ML75 | ML85 | ML100 | ML130 | ML160 | ML180 |

| Screw diameter(mm) | 75 | 85 | 100 | 130 | 160 | 180 |

| L/D | 26 to 33 | |||||

| Output(kg/h) | 100-120 | 100-180 | 200-300 | 400-600 | 600-800 | 800-1000 |

| Model | ML75B | ML85B | ML100B | ML130B | ML160B | ML180B |

| Screw diameter(mm) | 75 | 85 | 100 | 130 | 160 | 180 |

| L/D | 26 to 37 | |||||

| Output(kg/h) | 100-150 | 200-350 | 400 to 550 | 600 to 800 | 800 to 1000 | 1000-1200 |

| Model name | ML |

| output | 3mm Plastic pellets/granules/resins/plastic raw material |

| Machine parts | Belt conveyor, cutter compactor, main extruder, pelletizing unit, cooling system, silo, cabinet |

| Recycling material | PP/PE/LDPE/HDPE film, bag, fiber |

| Capacity range | 100kg/h to 1200kg/h |

| Feeding way | Conveyor, roll driving system |

| Screw diameter | 75mm to 200mm |

| Screw L/D | 26 to 33 |

| Screw raw material | 38CrMoAl or bimetallic |

| degassing | Natural degassing, vacuum degassing |

| Cutting type | Vertical pelletizing way, pull strip pelletizing |

| Cooling type | Water cool, air cool |

| voltage | Customized |

| Optional devices | Metal detector, water cooling system, feeding silo, vibration system |

| Delivery time | 40 to 60 days |

| Warranty time | 13 months |

| Technical supports | Machine layout, installation layout, engineer oversea service |

| certificate | CE/ SGS/ TUV/CO |

How it works:

Belt conveyor convey material into compactor with interlock control

Feeder and extruder is controlled by inverter

Various L/D for Various material

Natures degassing, vacuums degassing adopting for moisture

Water ring die face cutting for perfect pellets shape

Machine Detail Pictures

Note: Final pellets can be used for blwoing, extruding and injecting area!

Machine advantages:

1. One Step, All-in-One direct recycling(cutting, extrusion and pelletizing)

2. Balance feeding without the need for pre-cutting

3. Higher output capacity

4. Higher pellets quality

Category

Plastic Film Recycling Extruder

Plastic Recycle Pelletizing Machine

Waste Plastic Film /Bag Washing Line

Plastic Bottle Recycling Machine

Rigid Plastic Recycling Machine

PET Plastic Pelletizing Machine

Twin Screw Extruder

Plastic Auxiliary Equipment

Plastic Film Granulator

Plastic Pelletizer Machine

Waste Plastic Recycling Machine

Plastic Film Recycling Machine

PE Granulator

Plastic Granulator Machine

plastic shredder

Plastic Granules Making Machine

Product Search

News