|

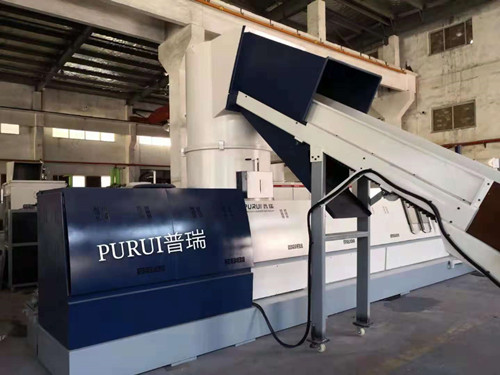

ML model extruder with compactor

Application: various low bulk density material, like plastic film, fiber, woven bag, non-wove cloth or washed loose scrap, online-trim waste

Advantages: wide application for various material recycling

Process plastic type: PE/PP/PET/PA/PS/ABS/BOPP/CPP/EPS

Recycle Material Sample

Main Technical Data

Model | ML85 | ML100 | ML130 | ML160 | ML180 | |

Capacity(kg/hr) | 150 to 200 | 200 to 300 | 450 to 500 | 600 to 800 | 800 to 1000 | |

Consumption(kwh/kg) | 0.27 | 0.28 | 0.29 | 0.3 to 0.31 | 0.31 to 033 | |

compactor | diamter | 900 | 1000 | 1200 | 1300 | 1500 |

| Fixed cutters | 5 | 12 | 13 | 13 | 15 |

| Rotary cutters | 2 groups, 4 pieces | 2 groups, 6 pieces | 3 groups, 9 pieces | 3 groups, 12 pieces | 3 groups, 12 pieces |

| motor | 37kW | 55kW | 90kW | 110kW | 160kW |

Extruder

| L/D | 33 to 42 | ||||

| motor | 55kW | 90kW | 132kW | 185kW | 250kW |

| Degassing way |

Nature degassing or vacuum degassing | ||||

| Screw rotating speed |

120rpm |

100rpm | |||

| Heating motor | 4*6 kW | 5*6.5kW | 5*10kW | 6*15kW | 6*18kW |

| Cooling motor | 4*0.3kW | 5*0.3kW | 5*0.55kW | 6*0.55kW | 6*0.55kW |

| Vacuum pump motor | 1.5kW | 2.2kW | 3kW | 4kW | 5.5kW |

Screen changing system | Plate screen changing system ( standard) Mesh size: 80mm to 110mm | |||||

| Column screen changing system (customer choosing) Mesh size: 80mm to 110mm | |||||

second stage extruder | L/D | 10 to 15 | ||||

| Screw diameter | 90mm | 110mm | 140mm | 180mm | 200mm |

| Rotating speed | 80rpm | 80rpm | 80rpm | 90rpm | 90rpm |

| motor | 30kW | 45kW | 55kW | 75kW | 90kW |

Pelletizing part | Watering ring pelletizing ( standard) | |||||

| Pull strip pelletizing way (accoring to PP material MFI ) | |||||

| Underwater pelletizing ( suitable for PET flake) | |||||

Novel advantages:

Compactor get equipped with cutter gate valve, which can control material feeding amount and cutting speed.

That do great help for extruder stable work and melt material temperature constant temperature

This design made ML model extruder is suitable for loose material and rigid material recycling.

General introduction:

From shredding compactor, the material is transported directly into the extruder by a belt conveyor without being pre-cut or compressed. The rate of material feeding is controlled automatically by the current of the extruder motor and main extruder screw rotating speed. This design will keep material with balance feeding, and protect material from blocking and melting in the shredding compactor.

Degassing parts: natural degassing/ vacuum degassing

Melting plastic is filtered by a continuous melt filter (plate hydraulic screen filter, double volume screen changer) available with or without back-flushing system. According to material type, the pelletizing way can be equipped with a water ring, strand or underwater pelletizing system.

2019 China International Plas Booth NO.2.1F21