|

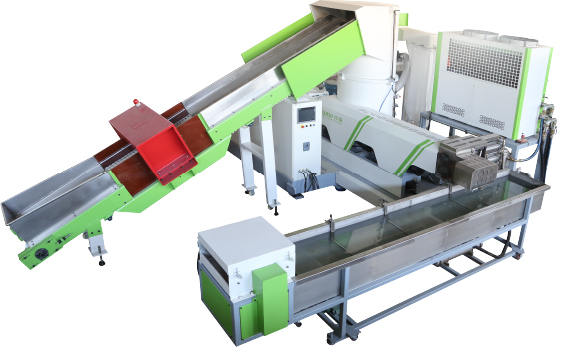

PP Non-woven Cloth Pelletizing Process and Recycling Extruder

PP non-woven bag pelletizing machine

processing capacity : 200kg/h to 800kg/h

power saving with high output

processing capacity : 200kg/h to 800kg/h

power saving with high output

General Intorduction:

To recycle waste PP non-woven cloth, we need consider its nylon trim.

As we all know, through high temperature, nylon can get plastification by melt.

Also, PURUI made extruder also can filter some Nylon by hydraulic screen changing system.

Machine Technical Parameter:

Advanced (high efficiency with power saving)

| Model | ML75B | ML85B | ML100B | ML130B | ML160B | ML180B |

| Screw diameter(mm) | 75 | 85 | 100 | 130 | 160 | 180 |

| L/D | 26 to 37 | |||||

| Output(kg/h) | 100-150 | 200-350 | 400 to 550 | 600 to 800 | 800 to 1000 | 1000-1200 |

The particular advantage of the ML model:

No need pre-heating and pre-cutting or other treatment of the material before extrusion.

It avoids the plastic precutting, the plastic bags and films and stretches can be fed directly in to the cutter compactor then crush, compress and heat, then it will go to the screw for plasticizing

Some washed 5% films can be feed directly, as it will be heated and dry in the compactor, then it will be degassed twice in the screw while plasticizing

Special designed screw and barrel, with experienced engineering we can offer and design for you the best screw and barrel to make the end pellets qualified

Cutter compactor:

As the conveyor directly connects with the compactor, the materials can follow the belt to cutter compactor, and the material will be cut and compressed. At the bottom of the cutter compactor equips with pipes with running water to cooling the material

Electricity Saving: 0.29-0.30kwh/kg

Category

Plastic Film Recycling Extruder

Plastic Recycle Pelletizing Machine

Waste Plastic Film /Bag Washing Line

Plastic Bottle Recycling Machine

Rigid Plastic Recycling Machine

PET Plastic Pelletizing Machine

Twin Screw Extruder

Plastic Auxiliary Equipment

Plastic Film Granulator

PP Granulator

Waste Plastic Recycling Machine

Plastic Film Recycling Machine

PE Granulator

Plastic Granulator Machine

plastic shredder

Plastic Granules Making Machine

Product Search

News