|

Plastic compounding line with High quality masterbatch with double screw

Quick Detail for Plastic compounding line with High quality masterbatch with double screw:

· Material of screw: W6Mo5Cr4V2,Bimetallic

· High-performance degassing

· See machine running when come to our factory

· Engineer supply when you buy the machine

· Design machine according to your material

· One year guarantee but offer all life after sales service

Description for Plastic compounding line with High quality masterbatch with double screw:

A. Features of masterbatch compounding line:

1. modular structure and fully intermeshed screw of great self-cleaning ablity and degassing property.

2. Bimetallic liner for extruder barrel,with superior wear resistance and corrosion resistance

3. Wide range of application by simply adjust configuration according to the detailed processing.

B. Applications fields of masterbatch compounding line:

The filler masterbatch machine in PURUI is our parallel co-rotating twin screw extruder specially designed for filler modified resin which have excellent mixing performance,good self-cleaning performance and flexible modular configuration characteristivs which make them suitable for processing different types of material.

Our company adopts new design concept for the screw and barrel to increase the extrusion section pressure.The new extrusion system has achieved good disperse ability,the masterbatch produced are bright,smooth, without spot and pores.

Note: depending on different material properties, various downstream equipments are needed.

Preparation of master batch:

Carbon black master-batch

Color master batch

Flame-retardant master-batch

Degradation master-batch

Other special functions master-batch

C. Specifications of masterbatch compounding line:

Technical parameter of TSSK series masterbatch compounding line (normal)

|

Model |

TSSK-20 |

TSSK-30 |

TSSK-35 |

TSSK-50 |

TSSK-65 |

TSSK-72 |

TSSK-92 |

|

Screw diameter(mm) |

21.7 |

30 |

35.6 |

50.5 |

62.4 |

71.2 |

91 |

|

Rotary speed(rpm)) |

600 |

400 |

400/600 |

400/500 |

400/500 |

400/500 |

400/500 |

|

Mainmotor power(kw) |

4 |

11 |

11/15 |

37/45 |

55/75 |

90/110 |

220/250 |

|

L/D |

32-40 |

28-48 |

32-48 |

32-48 |

32-48 |

32-48 |

32-40 |

|

Capacity(kg/h) |

2-10 |

5-30 |

10-80 |

20-150 |

100-300 |

300-6000 |

600-1000 |

Technical parameter of TSSK series masterbatch compounding line (high torque)

|

Model |

50B |

65B |

75B |

75D |

|

Screw diameter(mm) |

50.5 |

62.4 |

71.2 |

71.2 |

|

Rotary speed(rpm) |

500/600 |

500/600 |

500/600 |

500/600 |

|

Mainmotor power(kw) |

55/75 |

90/110 |

132/160 |

200/250 |

|

L/D |

28-48 |

28-48 |

28-48 |

28-48 |

|

Capacity(kg/h) |

120-280 |

180-400 |

250-650 |

500-1200 |

Competitive Advantage:

- Skillful manufacture

- Sophisticated technology

- Finely processed

- Latest technology

- Professional design

- Rational construction

- Durable in use,excellent quality

- Dependable performanc

- Extremely easy operation

- Selling well all over the world

- Efficient melt filter systems

- Excellent technical engineer team

D.Detailed machine photos of masterbatch compounding line

Electric control cabinet

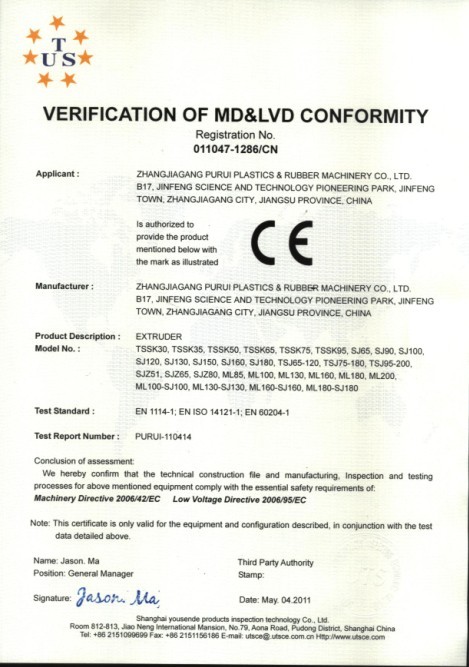

Certificate we’ve got